Log In

Log In

At Materiom we envision a future where materials regenerate nature and support human health. What does this mean in practice?

All useful materials created today – packaging, textiles, construction materials, you name it – impact life in our biosphere, whether that’s through the extraction of finite resources, toxins released during production, greenhouse gases emitted through transport, or pollution through littering or landfilling.

Plastic, for example, pollutes every marine and terrestrial ecosystem on Earth. Of the seven billion tonnes of plastic waste generated globally to date, less than 10% has been recycled, leaving the rest to be burned or dumped, clogging our soils and waterways, piling up in landfills, and threatening our health. 1.8 billion tonnes of greenhouse gas emissions were generated by the plastic life cycle in 2019 alone; a figure expected to more than double by 2060 as growth in petroleum plastics continues to increase. To address plastic pollution at its source, scientists and governments propose large-scale reduction of unnecessary plastics, increased circularity through reuse and recycling, and the innovation of sustainable substitute materials.

Materiom’s core focus is on the third pathway – accelerating the innovation of alternative materials that have a net-positive impact on the environment and society. We believe it is possible to create such “regenerative” materials by:

Importantly, we acknowledge that a material cannot be regenerative in isolation – its potential to regenerate depends on the infrastructure, communities, and ecosystems within which it exists. These and a range of other factors need careful consideration when weighing up a material substitution. Many well-intentioned companies switch to materials they describe as ‘biodegradable’ or ‘compostable’ under the misconception that a material alone is sustainable, whereas it is in fact only a system of production, collection, and reprocessing of a material that can be sustainable.

As stewards of regenerative materials innovation, we are working with organisations across the materials value chain to understand current obstacles and opportunities, and to build collective intelligence in a relatively new sector with a range of possible development pathways. We value all input from our peers, collaborators, and readers on the topic.

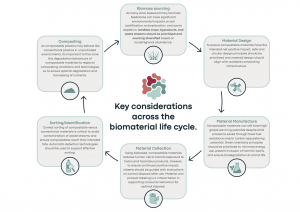

What are some of the most important factors to consider when striving for new materials that are good for people and the planet? We take a whole life cycle perspective – focusing on sourcing, production and end of life:

We aim for 100% biobased materials that are sustainably harvested from non-competitive biomass. This means materials that are made solely from ingredients of biological origin. Many ‘biobased’ products are not necessarily fully organic in composition which can compromise their ability to degrade safely in natural environments at the end of their lives. Wholly organic materials also avoid the harmful effects of petrochemical material sourcing and production, which range from climate change to pollution, affecting human and environmental health.

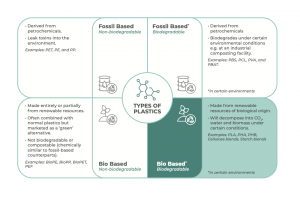

As shown in the summary below, materials marketed as ‘bioplastics’ can range from fully organic to fully fossil-based in composition, with varying levels of biodegradability and compostability depending on how they are engineered (more on this in the following section). The ASTM D6866 test and other radiocarbon-based testing methods can be used to quantify the biobased content of a material. Certification schemes for biobased content vary regionally, but as a general rule, claims and labelling should refer to the exact, measured share of biobased content in the product, for example: ‘product contains 95% biobased content’.

Graphic: Types of plastics inclusive of definitions and representative (non-exhaustive) examples

Graphic: Types of plastics inclusive of definitions and representative (non-exhaustive) examples

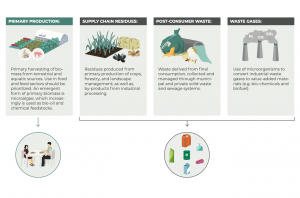

Feedstock types

It is important to source renewable, biobased feedstocks that are locally abundant and otherwise under-utilised or non-competitive in the context of land use and food security. Most biomaterials on the market today are made from primary agricultural crops such as sugar-cane, corn, and soy which may compete with arable land and water resources needed for food production, or encroach on critical natural ecosystems. By leveraging secondary biomass sources such as industrial byproducts and post-consumer food waste – we can reduce demand for primary crops which in turn reduces stress on our soils, land-use, and biodiversity.

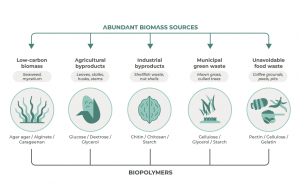

Materiom works with local communities and regional value chains to map, quantify, and valorise under-utilised biomass feedstocks such as land-less feedstocks (seaweed and mycelium), agricultural byproducts (e.g. leaves, stalks, husks and stems), industrial by-products (e.g. shell-fish waste, nut shells), municipal green waste (e.g. mown grass, culled trees) and unavoidable food waste (e.g. coffee grounds, peels, pits).

Graphic: Categories of under-utilised biomass and representative biopolymers (non-exhaustive) that can be extracted from them.

Graphic: Categories of under-utilised biomass and representative biopolymers (non-exhaustive) that can be extracted from them.

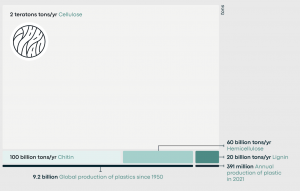

By deriving a biopolymer from a diversity of sources, we can better assure feedstock supply while lowering the risk of over-exploiting any one resource in a region. Cellulose, for example – the most abundant biopolymer on earth – can be derived from numerous sources including wood, plants, bacteria, and algae. The annual volume of cellulose produced in the biosphere (see figure below) dwarfs the annual production of petrochemical plastic – a high-potential abundant resource if leveraged sustainably through diversified sourcing and local feedback loops that respect regional carrying capacities.

With diversified feedstocks in mind, an innovation area requiring research and investment is the standardisation of biopolymers from multiple sources that may have different physicochemical characteristics. One potential pathway to overcome this is the advancement of biorefining processes that can aid uniformity and enable streamlined large-scale production.

It’s no use producing biobased, compostable materials using inordinate amounts of energy and water or inefficient, excessive logistics and transport. Truly regenerative materials should be made in a way that ensures a net-positive impact across the entire life cycle.

The Principles of Green Chemistry provide useful guidelines for a more sustainable production process and product, while life-cycle assessment (LCA) methodology is an invaluable tool for understanding environmental impacts and trade-offs associated with all the stages of the life cycle of a product, process, or service. LCA thinking is a very important starting point for anyone considering the design of a new biobased, compostable material, as it helps to quantify and cross-compare the holistic impacts of various material substitutions against the status quo, as well as other circular strategies including the reduction, reuse, and repair of materials and products. In doing so, one can prioritise the most favourable environmental outcomes across the whole system and avoiding shifting the burden from one stage of the life-cycle (e.g. sourcing) to the next (e.g. water usage).

Building a regenerative materials system entails designing compostable materials that return biological nutrients to soils at end of life. Research shows that biopolymers such as chitin, sodium alginate, carrageenan, keratin, gelatin, and whey protein have the potential to support the nutrient needs of crops as compost in regenerative agriculture systems. They can also add beneficial carbon and organic matter needed by plants and soil microbes back into soils, as well as enhancing its ability to sequester carbon (Gao, X., et al; Dziedzic, I., et al). What factors should be considered in striving for this end goal?

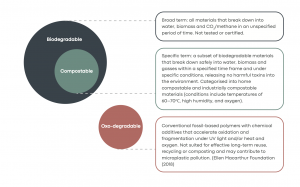

Definitions of compostable vs biodegradable vs oxo-degradable

In the current waste managements landscape, the terms compostable and biodegradable are often confused and misused. While biodegradable is a broad term pertaining to any material that can be broken down into water, biomass, and gases such as carbon dioxide and methane in an unspecified time frame, compostable materials are a subset of biodegradable materials that have been tested to ensure they break down safely into water, biomass, and gases within a specific time frame and under specific conditions, releasing no harmful synthetic toxins into the environment.

Organisation are moving away from ‘biodegradable’ as a qualifying term as it leaves too broad a window of interpretation: depending on their composition and engineering, biodegradable plastics could take years to biodegrade, releasing harmful microplastics and other substances into the environment in the process.

Materials deemed compostable must be certified against a regional standard – EN13432 is the current European standard – for industrial composting (conditions include temperatures of 60–70℃, high humidity, and oxygen) or meet the requirements of an appropriate home composting specification such as OK Compost Home certified by TUV Austria.

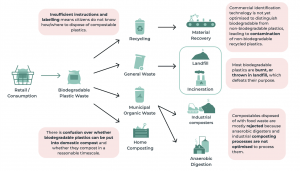

However, it is not enough to create a material that is ‘compostable’ on paper, yet lacks compatibility with the waste-processing facilities and systems in a region. In many regions around the world, compostable materials end up incinerated or in landfills due to insufficient labelling for consumers to make the right disposal choices, lack of appropriate composting facilities and infrastructure (anaerobic digesters and industrial composting are not optimised for biomaterials in addition to food and other organic waste), confusion and lack of knowledge around home composting, and insufficient sorting technologies to distinguish biodegradable from non-biodegradable materials with similar properties. They can also contaminate other waste streams, and the natural environment, reducing the efficiency and impact of the waste disposal system as a whole.

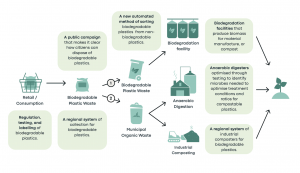

Opportunities to overcome these obstacles exist in the form of government interventions that prioritise regulation, testing, and labelling or compostable plastics, as well as fit-for-purpose collection, sorting, and industrial composting systems. Public campaigns on correct disposal of compostables and financial incentives that give value to a circular bioeconomy are equally important levers for change.

Acknowledging these challenges and opportunities further highlights the need for a whole value chain approach to regenerative materials innovation. Where value chain actors can come together to design regionally appropriate systems and materials from sourcing right through to end of life, there is rich potential to turn a linear waste economy into a nourishing and value-adding one.

Nature has, for billions of years, created vast quantities of materials that remain in healthy, regenerative cycles without landfill or waste. Can we look to this blueprint to reimagine industrial material systems and depart from the current linear mode that undermines our ability to sustain life on earth? Underpinning a low-carbon, waste-free materials economy is a mindset shift from degeneration to regeneration, from surviving to thriving, from doing ‘less bad’ to putting healthy life at the centre of industry. This shift in thinking is already underway in the fields of regenerative agriculture, tourism — and even business.

As with any systemic transition, pathways towards a regenerative materials economy are complex and nonlinear. They affect and are affected by policy, economics, labour markets, infrastructure, and social structures — all deeply contextual and different for every region around the world. They are fraught with obstacles, but rich with opportunities that can be unlocked only through a delicate balancing of interconnected moving parts. To accelerate a regenerative economy for materials, we call on actors across the value chain to:

This glossary borrows definitions from UCL Plastic Waste Innovation Hub | A Guide For Product Manufacturers Intending To Use Biodegradable Packaging and UNEP From Pollution to Solution: A global assessment of marine litter and plastic pollution

Biodegradable means a material can be decomposed under the action of microorganisms — such as bacteria, fungi, algae or earthworms into water, biomass, and gases such as carbon dioxide and/or methane. Biodegradability depends on environmental conditions such as temperature, humidity, the presence of oxygen, and microorganisms. To be truly meaningful, the term must be linked to the end products, to a timescale that is compatible with a human scale, and to the conditions of biodegradation.

Bioplastics are made using polymers that are either biosourced, biodegradable or both. It is for this reason that the term “bioplastic” should never stand alone and why it is necessary to specify, each time this word is used, the plastic’s origin (biosourced or not) and end of life (biodegradable or not).

Biopolymers are natural polymers derived from renewable resources of plants or animals. They can be directly synthesised by plants or animals such as polysaccharides (starch, cellulose, chitosan, etc.) proteins (collagen, gelatin, casein, etc.) and lignins, or synthesised from biological resources such as vegetable oils (rape, soybean, sunflower, etc.). Other biopolymers, such as PHA, are produced by microorganisms (bacteria) through fermentation from sugars and starch.

Biosourced polymers are manufactured, in part or in whole, from renewable biological resources. The sources of raw materials are very varied. We find everything related to biomass, organic matter, in particular starches, sugars and vegetable oils.

Compostable materials are a subset of biodegradable materials that break down safely into (in the case of plastics) water, biomass, and gases under composting conditions. Industrial composting conditions are the most favourable: temperatures of 60-70 ºC, high humidity, and oxygen. Materials that break down in industrial composters may not break down under home composting conditions. For industrial composting, standards apply: ISO 17088, EN 13432, ASTM 6400.

Composting is an aerobic transformation process (i.e. in the presence of oxygen) of fermentable materials under controlled conditions, used to obtain a stabilized fertilizing material, rich in humic compounds, called compost. It is accompanied by the release of heat and carbon dioxide. It is a process widely used, especially in agricultural environments, because compost helps amend soil by improving its structure and fertility.

End-of-life is a term used to indicate the stage of a product, process, or system when it is disposed of and/or recycled.

Home composting is a general term for the process by which organic (usually food and garden) waste is collected and placed in a container or heap to allow natural processes to turn it into compost. It is a manual process whereby the composition and process temperatures remain largely unregulated. Both aerobic and anaerobic conditions can occur in home composting, although aerobic conditions are more normal. The time frame for home composting depends on personal preference and the use to which the compost is put, but 3-12 months is typical.

Life-cycle assessment (LCA) is an environmental assessment methodology used to analyse the environmental impacts associated with resource utilisation and emissions at each stage of a product, process, or system’s life cycle.

Oxo-degradable plastics (or “fragmentable“, “oxofragmentable“, or even “biofragmentable“ or “oxo-biodegradable” plastics) are polymers of petrochemical origin containing pre-oxidants, such as mineral oxidizing additives, that promote their degradation into small pieces (until they become invisible to the naked eye). These plastics can fragment, under certain conditions (light, heat, etc.), but are not biodegradable according to current standards. In addition, these additives seem to contain heavy metals whose environmental effects are currently unknown. The new European Single-Use Plastic Products Directive, approved by the European Parliament on 27 March 2019, provides for the prohibition of these oxo-degradable plastics whatever their use.

Plastics are defined as synthetic organic polymers with thermo-plastics or thermo-set properties (synthesized from hydrocarbon or biomass raw materials), elastomers (e.g. butyl rubber), material fibres, monofilament lines, coatings and ropes (GESAMP 2019). Many plastics are produced as a mixture of different polymers and various plasticizers, colorants, stabilizers and other additives. Most plastics can be divided into two main categories: thermoplastics (capable of being deformed by heating), which include polyethylene, polypropylene and polystyrene; and thermoset (nondeformable), which include polyurethane, paints and epoxy resins. About 15 per cent of total synthetic polymer production consists of fibres, such as polyester and acrylic. Another significant component of marine litter is semi-synthetic material, such as cellulose nitrate and rayon, made from biomass (UNEP 2018b).